Abstract

Hydrogen is increasingly being discussed as clean energy for the goal of net-zero carbon emissions, applied in the proton-exchange-membrane fuel cells (PEMFC). The preferential oxidation of CO (PROX) in hydrogen is a promising solution for hydrogen purification to avoid catalysts from being poisoned by the trace amount of CO in hydrogen-rich fuel gas. Here, we report the fabrication of a novel bimetallic Pt-Fe catalyst with ultralow metal loading, in which fully-exposed Pt clusters bonded with neighbor atomically dispersed Fe atoms on the defective graphene surface. The fully-exposed PtFe cluster catalyst could achieve complete elimination of CO through PROX reaction and almost 100% CO selectivity, while maintaining good stability for a long period. It has the mass-specific activity of 6.19 (molCO)*(gPt)−1*h−1 at room temperature, which surpasses those reported in literatures. The exhaustive experimental results and theoretical calculations reveal that the construction of fully-exposed bimetallic Pt-Fe cluster catalysts with maximized atomic efficiency and abundant interfacial sites could facilitate oxygen activation on unsaturated Fe species and CO adsorption on electron-rich Pt clusters to hence the probability of CO oxidation, leading to excellent reactivity in practical applications.

Similar content being viewed by others

Introduction

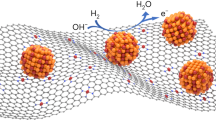

Hydrogen, as renewable and clean energy, will play an increasingly important role in meeting the world’s growing energy needs and avoiding the potential negative influence to climate change1. The proton-exchange membrane fuel cell (PEMFC) has been regarded as a promising candidate for the utilization of hydrogen, due to its high efficiency and low operating temperature2,3. However, the platinum electrode of the PEMFC is prone to be poisoned by CO leading to the loss of efficiency, which is attributed to the presence of small amounts of CO remaining in the industrial hydrogen produced by the reforming of hydrocarbons and water-gas shift reaction processes4,5. To remove the residual CO before feeding the hydrogen fuel gas to the PEMFC, the CO preferential oxidation (PROX) reaction is considered as an attractive route by selective CO oxidation in H2-rich stream6,7. However, since the PEMFC operation temperature is low, it remains challenging to achieve highly efficient oxidation of CO at low temperature.

Among various supported metal catalysts developed for the PROX reaction, platinum group metal (PGM) catalysts with excellent activity and stability have received much attention as potential candidates8,9. Unfortunately, it is widely known that monometallic PGM catalysts on inert supports have poor CO oxidation activity in PROX reaction especially at low temperature, e.g., room temperature, due to the limited O2 activation on the Pt surface adsorbed by CO5,10. So far, to improve the CO PROX catalytic performance at low temperature, intensive studies have been done over promoted PGM catalysts, in particular, by introducing various secondary reducible element into PGM catalysts11,12,13. One of the promoted catalysts is bimetallic alloy nanoparticles, in which the second element and Pt could form an intermetallic compound with their own specific crystal structure13,14. Chen and co-workers prepared a PtFe nano-alloy catalyst by a one-pot surfactant-free polyol process. They discovered that the high performance of Pt0.71Fe0.23/Al2O3 towards CO PROX reaction originated from the adsorption of CO and O2 on Pt and Fe, respectively, leading to the efficient O2 activation on Fe2+ species. But these active species would be oxidized to Fe3+ under the PROX condition, causing the deactivation of supported PtFe alloy catalysts15. Another type of promoted catalysts is reducible metal oxides-promoted PGM catalysts that use reducible oxides as supports, such as CeO2, Fe2O3, and Co3O4, sometimes with the presence of secondary metal (Fe, Co, Ni, Cu) as promoter16,17,18. Zhang et al. reported a novel catalyst consisting of only single Pt atoms that were uniformly dispersed on FeOx nanocrystallites with high activity for preferential oxidation of CO in H2 due to the surface oxygen vacancy of iron oxides and the strong binding of Pt atoms with positive charge12. Recently, Lu et al. showed that atomically dispersed iron hydroxides on Pt nanoparticles using the atomic layer deposition (ALD) method enabled completely selective CO removal through the PROX reaction. The Fe1(OH)x-Pt single interfacial sites could readily react with CO and facilitate oxygen activation19. Overall, the promoted PGM catalysts by the addition of a secondary element have exhibited improved oxidation activities at low temperature for the PROX reaction due to the presence of additional accessible sites for oxygen such as oxygen vacancy or reducible metal oxides/hydroxides provided by secondary metal sites to further react with CO. Nonetheless, the main species in these promoted catalysts mentioned above were commonly the metal nanoparticles over 2 nm in size which did not achieve the optimal utilization of the metal atoms in PtM catalysts. The prepared promoted PGM catalysts only offered a limited number of interfacial sites for the adsorption of CO and O2, and it is usually hard to maximize the interfacial density. Thus, the insights are in urgent need into achieving the size of metal species with sub-nano level or even atomic level. Besides, only a few catalysts reported in literatures showed superior oxidation activity and selectivity at low temperature, particularly, at room temperature, which is critical for PEMFC operation conditions6,20. In recent years, fully exposed cluster catalysts (FECCs) with ensemble sites and atomic dispersion have drew attention as active species in many catalytic reactions21,22,23. As a result, it is of great interests to construct highly dispersed and fully exploited interfacial sites via the addition of the secondary element in hopes of improving the catalytic performance for CO PROX reaction at low temperature.

In this work, we reported a novel catalyst, fully-exposed bimetallic Pt-Fe clusters anchored on the defective graphene/nanodiamond (ND@G) hybrid support, where the atomically dispersed and fully-exposed Pt cluster are bonded with neighboring Fe atom to provide abundant Pt-Fe interfaces. The fully-exposed Pt-Fe clusters are highly efficient for preferential oxidation of CO with complete CO conversion and 100% CO selectivity at low temperature, and show excellent oxidation activity (high CO oxidation mass-specific reaction rate of 6.19 (molCO)*(gPt)−1*h−1 at 30 °C) with ultralow metal loading. The fully-exposed Pt-Fe clusters with high atomic efficiency of both two metals and abundant Pt-Fe active interfaces contribute to the improved catalytic performance. Besides, the distinctive Pt-Fe interfacial sites can activate CO and O2 molecules to accelerate CO oxidation with lowered apparent activation energy.

Results

Structural characterizations of PtFe cluster catalysts

Fully-exposed Pt-Fe clusters were fabricated on defective graphene/nanodiamond (ND@G) hybrid support through a facile deposition-precipitation method with theoretical loadings (Pt: 0.75 wt%, Fe: 0.2 wt%), which was denoted as 0.75Pt0.2Fe/ND@G (Table S1). The morphology and structure of 0.75Pt0.2Fe/ND@G were initially investigated by Aberration-corrected high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM). As revealed in Figs. 1a, 1b and Fig. S1, ultrasmall Pt-Fe clusters were fully exposed and uniformly dispersed on the ND@G support, without any crystallized platinum or iron nanoparticles21,24. Meanwhile, the X-ray diffraction (XRD) pattern of the catalyst (Fig. S2) showed only typical diffraction peaks of graphene and nanodiamond25,26, confirming that no crystalline metal was formed, in line with the STEM images of 0.75Pt0.2Fe/ND@G. The corresponding energy dispersive X-ray (EDX) mapping results of 0.75Pt0.2Fe/ND@G (Fig. 1c) indicated that platinum and iron element displayed simultaneously within the cluster areas on the support surface. The electron energy loss spectroscopy (EELS) (Fig. S3) further provided strong evidence of the presence of atomically dispersed iron atom structure in the cluster area, indicating that the Pt-Fe clusters mainly consisted of fully-exposed Pt clusters and highly dispersed Fe atoms. As shown in the magnified HAADF-STEM images (Fig. 1d), several compact spots, with different brightness caused by different Z-contrast of Pt and Fe, were packed loosely together to form atomic clusters marked by the rectangles, which consisted of several (mostly 3-5) Pt atoms and a neighboring Fe atom. Such clusters were distributed homogeneously on the surface of the ND@G substrate. The intensity surface plot images of circled clusters in Fig. 1e, f intuitively distinguished the Pt and Fe atoms due to the difference of signal intensity contribution between Pt and Fe atoms, confirming the formation of fully-exposed Pt-Fe clusters. Using a similar synthetic method, the 0.75Pt/ND@G catalyst with monometallic platinum clusters was obtained. From STEM images and intensity profiles analysis of 0.75Pt/ND@G (Fig. S4), the similar cluster structure with single-atom-layer thickness highly and disorderly dispersed on the support27,28.

a, b HAADF-STEM images of 0.75Pt0.2Fe/ND@G at high magnification. c Energy-dispersive X-ray (EDX) mapping images of 0.75Pt0.2Fe/ND@G catalyst. d, e The high resolution HAADF-STEM image of the 0.75Pt0.2Fe/ND@G, where representative isolated Pt, Fe atoms and atomic Pt-Fe clusters are highlighted by red, green circles and dashed blue rectangles, respectively. f 3-D intensity surface plot and intensity range shown for the dashed regions of the image in e. Scale bar: a, 2 nm; b 2 nm; c, 2 nm; d 0.5 nm; e 0.5 nm.

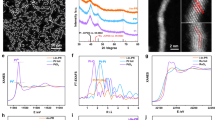

To probe the electronic structure of the fully-exposed Pt-Fe cluster for 0.75Pt0.2Fe/ND@G, X-ray photoelectron spectroscopy (XPS) and X-ray absorption spectrometric (XAS) measurements were performed. The XPS analysis (Fig. S5) showed that the Pt 4 f peak of 0.75Pt0.2Fe/ND@G was shifted to lower binding energy compared to that of 0.75Pt/ND@G, indicating that Pt electronic states were modified by Fe in fully-exposed Pt-Fe clusters via electron transfer from Fe to Pt atoms14,29. Temperature programming desorption of CO (CO-TPD) experiments (Fig. S6) further suggested that 0.75Pt0.2Fe/ND@G catalyst had higher CO desorption temperature than 0.75Pt/ND@G due to electron-rich Pt clusters, in agreement with the XPS results. From the normalized X-ray absorption near-edge structure (XANES) curves at the Pt-L3 edge (Fig. 2a), the white line intensity of 0.75Pt0.2Fe/ND@G decreased in compared to that of 0.75Pt/ND@G, which could be attributed to the electron-rich Pt clusters in 0.75Pt0.2Fe/ND@G30. Correspondingly, the 0.75Pt0.2Fe/ND@G catalyst exhibited the higher absorption energy than 0.2Fe/ND@G at the Fe K-edge (Fig. 2b), indicating the electron-deficient feature of Fe atoms in 0.75Pt0.2Fe/ND@G. Furthermore, Fourier-transform extended X-ray absorption fine structure (FT-EXAFS) spectra (Figs. 2c and 2d) were provided to clarify the local configurations of atomically dispersed Pt and Fe in fully-exposed Pt-Fe clusters. 0.75Pt0.2Fe/ND@G and 0.75Pt/ND@G had the same weak peaks at 2.00 Å and 2.70 Å at Pt L3-edge attributed to Pt-O/C and Pt-Pt paths, respectively, indicating high dispersion of Pt species. Besides, the first Fe-O/C peak located at around 1.96 Å displayed both 0.75Pt0.2Fe/ND@G and 0.2Fe/ND@G with the same Fe loading prepared by the similar method at Fe K-edge. It was evidenced that Pt and Fe species could be anchored on ND@G through M(Pt/Fe)-C bonding, which was further verified by the appearance of M(Pt/Fe)-C peak at 282.9 eV in C 1 s XPS spectra (Fig. S7)31. Interestingly, the second coordination peak at 2.56 Å of 0.75Pt0.2Fe/ND@G showed a shift compared to that of 0.2Fe/ND@G assigned to the Fe-Fe path according to Fe foil. It inferred the change of neighbor metal atom shell around the Fe atom, demonstrating the formation of Pt-Fe coordination. Then, the obtained EXAFS fitting results for 0.75Pt0.2Fe/ND@G (Fig. 2e-f, Fig. S8 and Table S2–3) showed that the coordination number of Pt-Fe and Pt-Pt were 0.6 and 2.5 at Pt L3-edge, and the coordination number of Pt-Fe and Fe-Fe were 3.4 and 1.3 at Fe K-edge, respectively32. Combined with the STEM images, the atomically dispersed and fully-exposed Pt clusters bonded with iron species that were primarily present in the atomically dispersed state. Such atomic configurations featured with the fully-exposed Pt-Fe clusters via Pt-Fe interfaces that were immobilized on the support by M(Pt/Fe)-C bonds. To corroborate this result, the wavelet transform (WT) analysis of Fe EXAFS was carried out33,34,35. As shown in Fig. 2g, 0.2Fe/ND@G displayed the intensity maximum at 5.0 Å−1 and 7.9 Å−1, which were attributed to the Fe-O/C and Fe-Fe paths, respectively, according to the WT contour plots of Fe foil and Fe2O3 references. In contrast, for the WT signal of 0.75Pt0.2Fe/ND@G, one intensity maximum at around 6.1 Å−1 was exclusively observed, which was assigned to the Pt-Fe coordination.

a XANES and c FT-EXAFS spectra at the Pt L3-edge (without phase correction) of the 0.75Pt/ND@G and 0.75Pt0.2Fe/ND@G; b XANES spectra and d FT-EXAFS at the Fe K-edge of the 0.2Fe/ND@G and 0.75Pt0.2Fe/ND@G. e, f The corresponding Pt L3-edge and Fe K-edge EXAFS fitting curves for 0.75Pt0.2Fe/ND@G catalyst at R-space, respectively. g Fe K-edge WT-EXAFS of 0.2Fe/ND@G, 0.75Pt0.2Fe/ND@G and the references samples.

Catalytic performance for PROX oxidation

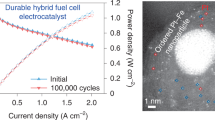

The preferential oxidation of CO in hydrogen (PROX) was studied to understand the role of fully-exposed Pt-Fe clusters. The 0.75Pt/ND@G catalyst with similar platinum structures of atomic clusters could reach a maximum CO conversion of 85% at 60 °C (Fig. S11). In contrast, by introducing Fe species, the 0.75Pt0.2Fe/ND@G catalyst dramatically improved the oxidation activity by achieving a full CO conversion at around room temperature (30 °C), with a high space velocity of 45,000 mL g−1 h−1 and 100% CO selectivity (Fig. 3a). However, 0.75Pt0.2Fe/SiO2 with the same Pt and Fe loadings showed low activity at room temperature, due to the presence of unevenly distributed metal nanoparticles which were observed in the STEM and XRD results of 0.75Pt0.2Fe/SiO2 (Fig. S9–10). In addition, the mass-specific reaction rate of 0.75Pt0.2Fe/ND@G at 30 °C was 6.19 (molCO)*(gPt)−1*h−1, which was higher than those of noble-metal catalysts reported in literatures (Fig. 3b, c and Table S4). The good stability of the PROX reaction at low CO conversion could be evaluated for more than 100 h at 30 °C for the 0.75Pt0.2Fe/ND@G catalyst (Fig. 3d). In the presence of water and CO2 (Fig. S12), the catalyst was still stable in the reaction stream without obvious activity drop. After the PROX reaction, we employed a comprehensive structure characterization of the used catalyst. Combined with the STEM images and XAS results (Fig. S13–14), the detailed structure of used 0.75Pt0.2Fe/ND@G catalyst was still better maintained with typical fully-exposed Pt-Fe clusters. The iron species were slightly oxidized after the PROX reaction, as observed in the Fe K-edge XAS spectra for the used catalyst. Notably, the 0.75Pt0.2Fe/ND@G catalyst could also achieve 100% CO conversion at low temperature under the PROX reaction with excess oxygen (Fig. S15). Finally, as a side note, the 0.75Pt0.2Fe/ND@G catalyst exhibited excellent performance for CO oxidation in the absence of hydrogen with a high TOF at 30 °C in comparison with other reported catalysts and robust stability (Fig. S16 and Table S5).

a CO conversion and selectivity of 0.75Pt0.2Fe/ND@G catalyst in PROX reaction. Reaction conditions: 1% CO, 0.5% O2 and 48% H2 balanced in He; the space velocity is 45000 mL g−1 h−1. b Mass specific rates of various PtFe catalysts at 30 °C in PROX reaction. c Comparison of the specific rate with reported metal catalysts as a function of their reaction temperature in PROX reaction. d Stability of the 0.75Pt0.2Fe/ND@G catalyst in the PROX reaction under the high space velocity (GHSV = 180,000 mL g−1 h−1) at 30 °C.

CO oxidation mechanism studies

To verify the promoted oxidation activity caused by the Pt-Fe interfacial effect, we evaluated the catalytic performance in the CO PROX reaction by regulating the Fe loading from 0.1 wt% to 0.3 wt%. Compared with 0.75Pt/ND@G, 0.75Pt0.1Fe/ND@G showed an increasing activity at 30 °C due to the introduction of a small amount of iron, and the oxidation activity reached maximum with the Fe dopant of 0.2 wt%, whereas a further increase of Fe loading decreased the performance (Fig. 4a, Fig. S17 and Table S1). The improved reaction rate after the introduction of iron for these PtFe catalysts suggested that the Pt-Fe interfacial sites were speculated as the active centers. Kinetic studies of the catalysts with different Fe loading revealed that the similar apparent activation barriers for a series of PtFe catalysts supported on ND@G distinctly were lower than that of 0.75Pt/ND@G, which might indicate the different reaction mechanism or active site among those PtFe catalysts (Fig. 4b). The structures of catalysts with different Fe loadings were further investigated (Fig. S18–24, and Table S2–3). The XRD results revealed no diffraction peak of metals appeared other than those corresponding to the support, indicating that Pt-Fe species were highly dispersed on ND@G for PtFe catalysts with different Fe loadings. Specifically, for the 0.75Pt0.1Fe/ND@G, a similar structure was elaborated from the STEM images. The related EDX mapping images (Fig. S19–20) and the XAS results (Fig. S23) were similar with those of 0.75Pt0.2Fe/ND@G, suggesting that the fully-exposed Pt-Fe clusters with Pt-Fe interfacial sites could react efficiently with CO and O2. However, for the 0.75Pt0.3Fe/ND@G, more iron species around clusters and ND@G-supported iron species were observed in the STEM images and EDX mapping results (Fig. S21–22), except for the fully-exposed Pt-Fe clusters. Meanwhile, the EXAFS results showed the Fe-O-Fe coordination peak at the high shell was increased, suggesting the formation of iron clusters in line with the STEM of 0.75Pt0.3Fe/ND@G. Fe 2p XPS patterns (Fig. S24) showed more oxidized Fe species for 0.75Pt0.3Fe/ND@G. Therefore, it was presumed that the weakened performance in 0.75Pt0.3Fe/ND@G catalyst could be attributed to the aggregation of many iron species and the decreased number of isolated Pt-Fe interfacial sites.

a The correlation between Fe loading of PtFe/ND@G catalysts and catalytic performance for PROX reaction at 30 °C. b Apparent activation energies of various PtFe/ND@G catalysts with different Fe loading in PROX reaction. c In situ DRIFTS study of CO adsorption during He purging and d co-adsorption CO and O2 on 0.75Pt0.2Fe/ND@G catalyst. XPS spectra of 0.75Pt0.2Fe/ND@G catalyst after in situ reduction at 400 °C and followed by the introduction of reactant gases (1% CO, 0.5% O2 and 48% H2 balanced with He at 30 °C for Pt 4 f (e) and Fe 2p (f)).

Moreover, to explore the promotional effects of iron species for PtFe/ND@G catalysts, we conducted the in situ DRIFTS experiments to study the adsorption of reacting molecules15,36. For 0.75Pt/ND@G, the main CO chemisorption peak located at 2061 cm−1 in the broad peak, assigned to linear CO on Pt clusters (Fig. S25a). However, the addition of iron led to the red shift of linear adsorbed CO signal to 2051 cm−1 for 0.75Pt0.2Fe/ND@G (Fig. 4c), confirming the charge transfer from Fe to Pt in line with the XPS and XANE results. We also employed in situ DRIFTS experiments under the reaction condition (1% CO, 1% O2/He flow). The blue shift of linear CO occurred over 0.75Pt/ND@G after the introduction of oxygen (2061 cm−1 to 2067 cm−1), which reflected the decreased back-donation of electrons from Pt to CO (Fig. S25). This result indicated the co-adsorption of CO and O2 on Pt clusters16. As shown in Fig. 4d, the CO adsorption band was slight shift (2054 cm−1) in the presence of oxygen compared to the band (2051 cm−1) after CO adsorption, which suggested that O2 was adsorbed more likely on the Pt-Fe interface and had a weak effect on Pt sites. The in situ XPS results were collected after hydrogen reduction at 400 °C and 30 min of time-on-stream in CO oxidation (30 °C) to study the real metal species states during the reaction. The shift to the higher binding energy of Pt 4 f (Fig. 4e) indicated that Pt species could be slightly oxidized on Pt-Fe interfacial sites after PROX reaction, which was consistent with the in situ DRIFTS results. The Fe 2p3/2 peaks of 0.75Pt0.2Fe/ND@G catalyst after reduction (Fig. 4f) mainly were located at 706.9 eV and 711.5 eV, ascribed to FexC and Fe3+.37,38 These peaks could be explained by the existence of iron species with positive charge in Fe XAS and metal-C bonding in C XPS results, indicating that iron species of fully-exposed Pt-Fe clusters were anchored by the surrounding carbon on the ND@G surface and other iron oxide species were difficult to reduce on the support. After the PROX reaction for 30 min, a new Fe 2p3/2 peak at 709.8 eV appeared, indicating that Fe species of fully-exposed Pt-Fe clusters were presented as Fe2+ for the activation of oxygen as active sites during the PROX reaction, as reported previously.15,17 Therefore, the activated oxygen species on Fe atoms readily reacted with CO adsorbed on Pt clusters for interfacial Pt-Fe active sites of fully-exposed Pt-Fe clusters, leading to the outstanding catalytic performance15,29. Combined with in situ DRIFTS and XPS results, the obtained relationship between Pt-Fe structures and their properties for the CO PROX reaction with different iron content verified that identified Pt-Fe interfacial sites in fully-exposed bimetallic Pt-Fe clusters were highly efficient for the CO PROX reaction at low temperature.

DFT calculations

To elucidate the origin of promoted oxidation activity of the 0.75Pt0.2Fe/ND@G catalyst, density functional theory (DFT) calculations were carried out to understand the CO oxidation mechanism of fully-exposed Pt-Fe clusters. Firstly, based on the structural characterization, a Pt4Fe1@Gr model with four platinum atoms and an iron atom anchored on four-carbon-vacancy of graphene was constructed to simulate the fully-exposed Pt-Fe cluster on ND@G. Three alternative Pt4Fe1 candidate structures were also examined which were later ruled out due to the conflicts between the experimental results of coordination numbers and calculated energy (Fig. 5a,b and Table S6). To further unravel the local structure of Pt4Fe1@Gr, we investigated the thermodynamic stability of Pt4Fe1@Gr involving oxygen species. Considering the experimental condition with hydrogen reduction treatment at high temperature, it was observed that oxygen species were not stable on Pt4Fe1@Gr to form H2O (Table S7 and S8).

a Top view and b side view of the DFT-optimized structures of 0.75Pt0.2Fe/ND@G after reduction. c DFT optimized structure of Pt4Fe1O@Gr model. d Energy profile of the CO oxidation on a Pt4Fe1@Gr model and the structures of intermediates and transition states. Here the Fe, O, C and Pt atoms are in yellow, red, gray and blue, respectively.

On the Pt4Fe1@Gr model catalyst, CO preferred to adsorb on Pt ensemble sites while O2 was adsorbed on the Pt-Fe interface (Fig. S26 and Table S9). Interestingly, when CO molecules were adsorbed to a high converge on Pt sites (5CO*), the adsorbed oxygen was easily dissociated with a low barrier of 0.1 eV, of which one O* was embedded in Pt4Fe1 to form a stable active structure (Pt4Fe1O@Gr) and other O* reacted readily with CO adsorbed on adjacent Pt site to release CO2 with a barrier of 0.56 eV (Fig. 5c, Fig. S27 and Table S10). Subsequently, on the carbon vacancy anchored Pt-Fe interface, adsorbed CO and O2 readily reacted to generate OCOO* intermediate with a barrier of 0.21 eV and then leaded to the formation of CO2 with a barrier of 0.46 eV (Fig. 5d, Fig. S28 and Table S11). This reaction was exothermic by 2.53 eV. Finally, another CO was adsorbed on the Pt site and attacked the remaining O atom on the Fe site to produce the second CO2 with a barrier of 0.76 eV and a reaction energy of −1.02 eV. Simultaneously, the catalytic reaction cycle was completed and the calculation indicated that this step was rate-determining.

Discussion

We firstly synthesized fully-exposed Pt-Fe clusters anchored on the defective graphene surfaces via a facile deposition-precipitation method. The structure analysis suggested Pt-Fe interfacial sites were fabricated as active sites by several platinum atoms bonded with neighboring iron atom in the bimetallic Pt-Fe cluster. The fully-exposed Pt-Fe cluster catalyst exhibited excellent catalytic performance for the PROX reaction with 100% CO conversion and selectivity at low temperature, especially with the better mass-specific activity than those reported so far at room temperature, while maintaining good stability for a long period. A fully-exposed Pt-Fe cluster with maximized atomic utilization and abundant interfacial sites could facilitate O2 activated by the neighboring unsaturated Fe site and readily react with adsorbed CO on the fully-exposed Pt cluster to form carbon dioxide on the Pt-Fe interfacial sites, thus resulting in the excellent catalytic performance.

Methods

Catalysts preparation

ND@G was prepared by the calcination of nanodiamond (ND) at 1100 °C for 4 h in argon to reconstruct to the defect-rich graphene surface. The PtFe/ND@G catalysts with different Fe loadings (wt(Fe) = 0.1%, 0.2%, 0.3%) were synthesized by a deposition-precipitation method. Firstly, 200 mg ND@G was dispersed in 25 ml deionized water to achieve a homogeneous suspension under 30 min sonication. Then, the ND@G suspension was heated to 100 °C in oil bath followed by the addition of 0.65 g sodium formate. A solution of H2PtCl6 ∙ 6H2O and Fe(NO3)3 ∙ 9H2O was added dropwise into the suspension under continuous stirring for 1 h. Afterwards, the mixture was cooled on standing for 6 h, collected by filter and dried at 60 °C for 12 h under vacuum. Finally, the powders were reduced in hydrogen flow (10% H2/He) at 400 °C for 1 h. The Pt and Fe contents controlled on demand during the preparation process were 0.75 wt% Pt and 0.1, 0.2, 0.3 wt% Fe, respectively, corresponding to 0.75Pt0.1Fe/ND@G, 0.75Pt0.2Fe/ND@G, and 0.75Pt0.3Fe/ND@G. Similarly, the 0.75Pt/ND@G with 0.75 wt% Pt and 0.2Fe/ND@G with 0.2 wt% Fe catalysts were prepared under identical synthesis conditions, but without Fe(NO3)3 ∙ 9H2O and H2PtCl6 ∙ 6H2O, respectively. As comparison, we also prepared 0.75Pt0.2Fe/SiO2 (0.75 wt% Pt and 0.2 wt% Fe) using the impregnation method.

Characterizations

HAADF-STEM images were recorded by a JEOL JEM ARM 200CF Cs-corrected cold field-emission scanning transmission electron microscope at 200 kV accelerating voltage. The electron energy loss spectra (EELS) was carried out using Nion HERMES100 electron microscopy operated at 60 kV. X-ray diffraction (XRD) patterns were collected by an X-ray diffractometer (Bruker Smart APEX II) using a Cu Kα source at a scan rate of 2° min−1. The X-ray Photoelectron Spectroscopy (XPS) was performed at ESCALAB 250 instrument with Al Kα radiation. All spectra were calibrated based on the sp3 carbon feature (286.8 eV). The dispersion of Pt species on catalysts was measured by the H2-O2 titration on a Micromeritics AutoChem II 2920 apparatus equipped with a thermal conductive detector (TCD). The actual platinum and iron contents of the catalysts were determined by inductively coupled plasma atomic emission spectrometer (ICP-AES, Leeman-Prodigy 7). The X-ray absorption fine structures (XAFS) measurements were analyzed at the BL14W1 station in Shanghai Synchrotron Radiation Facility (SSRF, 3.5 GeV, 250 mA in maximum, Si (111) double-crystals). The energy was calibrated accordingly to the absorption edge of pure Pt and Fe foil. Before XAFS experiments, the as-prepared samples were transferred to a glove box for tableting without exposure to air. In situ diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) experiments of 0.75Pt/ND@G and 0.75Pt0.2Fe/ND@G were performed on a Thermo Scientific Nicolet IS10 Fourier transform infrared spectrometer equipped with an MCT detector. The samples were pretreated in 10%H2/He at 400 °C for 1 h and cooled down to 30 °C under He flow. The corresponding spectrums were recorded for 25 min during He purging after CO saturated adsorption for 30 min. Then the catalysts were exposed to the reaction gas (1%CO, 1%O2/He) for 30 min and the spectrums were connected. All results were obtained by averaging 64 scans with a resolution of 4 cm−1.

Reaction evaluation

The PROX reactions were carried out in a quartz-bed flow reactor, equipped with an online gas chromatography instrument (Agilent 7890B with a TCD detector). 20 mg catalysts diluted with 200 mg quartz sands were reduced in hydrogen flow (10% H2/He) at 400 °C for 1 h. The PROX reaction was conducted in a temperature range of 30 °C −200 °C, where the reaction gas feed consisted of 1%CO, 0.5%/1% O2 and 48% H2 in helium at a total flow rate of 15 mL/min. CO oxidation was carried out with 1 vol% CO and 1 vol% O2 with a balance of He, and the space velocity is 72,000 mL g−1 h−1. Kinetic measurements were performed in the same reactor. The mass specific rates and activation energy were acquired with the CO conversion below 20% by increasing the space velocity.

Computational details

All DFT calculations were performed with the VASP package39,40. The electron−ion interactions were described with the projected augmented waves (PAW) method41,42. The PBE exchange-correlation was used43,44. The gamma point was used in the Brillouin zone sampling45. The plane-wave cutoff energy used was 400 eV. The structural optimization of all the atoms was carried out using a convergence criterion of 0.03 eV/Å for the atomic forces. Gaussian smearing with 0.05 eV was applied for the Brillouin-zone integration. Transition state searches were performed using the automated relaxed potential energy surface scan46 and harmonic frequency calculations were employed to ensure that the optimized transition states possess exactly one imaginary frequency.

Data availability

The data supporting this article and other findings are available from the corresponding authors upon request. Source data are provided with this paper.

References

Lubitz, W. & Tumas, W. Hydrogen: an overview. Chem. Rev. 107, 3900–3903 (2007).

Lin, L. et al. Low-temperature hydrogen production from water and methanol using Pt/a-MoC catalysts. Nature 544, 80–83 (2017).

Wu, J. F. et al. A review of pem fuel cell durability: degradation mechanisms and mitigation strategies. J. Power Sources 184, 104–119 (2008).

Choudhary, T. V. & Goodman, D. W. CO-free fuel processing for fuel cell applications. Catal. Today 77, 65–78 (2002).

Cao, S. F. et al. High-loading single Pt atom sites [Pt-O(OH)x] catalyze the CO PROX reaction with high activity and selectivity at mild conditions.Sci. Adv. 6, eaba3809 (2020).

Liu, K., Wang, A. Q. & Zhang, T. Recent advances in preferential oxidation of CO reaction over platinum group metal catalysts. ACS Catal. 2, 1165–1178 (2012).

Oh, S. H. & Sinkevitch, R. M. Carbon-monoxide removal from hydrogen-rich fuel-cell feedstreams by selective catalytic-oxidation. J. Catal. 142, 254–262 (1993).

Park, E. D., Lee, D. & Lee, H. C. Recent progress in selective CO removal in a H2-rich stream. Catal. Today 139, 280–290 (2009).

Pan, Y. B. et al. Computation-guided development of Platinum Alloy catalyst for carbon monoxide preferential oxidation. ACS Catal. 8, 5777–5786 (2018).

Lin, J., Wang, X. D. & Zhang, T. Recent progress in CO oxidation over Pt-group-metal catalysts at low temperatures. Chin. J. Catal. 37, 1805–1813 (2016).

Cai, J. M. et al. Highly dispersed Pt studded on CoOx nanoclusters for CO. preferential Oxid. H2. J. Mater. Chem. A 8, 10180–10187 (2020).

Qiao, B. et al. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 3, 634–641 (2011).

Alayoglu, S., Nilekar, A. U., Mavrikakis, M. & Eichhorn, B. Ru-Pt core-shell nanoparticles for preferential oxidation of carbon monoxide in hydrogen. Nat. Mater. 7, 333–338 (2008).

Komatsu, T., Takasaki, M., Ozawa, K., Furukawa, S. & Muramatsu, A. PtCu intermetallic compound supported on alumina active for preferential oxidation of CO in hydrogen. J. Phys. Chem. C. 117, 10483–10491 (2013).

Zhang, H. et al. Construction of ultrafine and stable PtFe nano-alloy with ultra-low Pt loading for complete removal of CO in PROX at room temperature. Appl. Catal. B 180, 237–245 (2016).

Lin, J. et al. Design of a highly active Ir/Fe(OH)x catalyst: versatile application of Pt-group metals for the preferential oxidation of carbon monoxide. Angew. Chem. Int. Ed. 51, 2920–2924 (2012).

Fu, Q. et al. Interface-confined ferrous centers for catalytic oxidation. Science 328, 1141–1144 (2010).

Chen, G. X. et al. Interfacial effects in iron-nickel hydroxide-platinum nanoparticles enhance catalytic oxidation. Science 344, 495–499 (2014).

Cao, L. N. et al. Atomically dispersed iron hydroxide anchored on Pt for preferential oxidation of CO in H2. Nature 565, 631–635 (2019).

Qiao, B. T. et al. Ferric oxide-supported Pt subnano clusters for preferential oxidation of CO in H2-rich gas at room temperature. ACS Catal. 4, 2113–2117 (2014).

Peng, M. et al. Fully Exposed Cluster Catalyst (FECC): Toward rich surface sites and full atom utilization efficiency. ACS Cent. Sci. 7, 262–273 (2021).

Deng, Y. C. et al. Few-atom Pt ensembles enable efficient catalytic cyclohexane dehydrogenation for hydrogen production. J. Am. Chem. Soc. 144, 3535–3542 (2022).

Dong, C. Y. et al. Fully exposed palladium cluster catalysts enable hydrogen production from nitrogen heterocycles. Nat. Catal. 5, 485–493 (2022).

Liu, J. et al. Origin of the robust catalytic performance of nanodiamond–graphene-supported Pt nanoparticles used in the propane dehydrogenation reaction. ACS Catal. 7, 3349–3355 (2017).

Huang, F. et al. Anchoring Cu1 species over nanodiamond-graphene for semi-hydrogenation of acetylene. Nat. Commun. 10, 4431 (2019).

Lin, Y. M., Sun, X. Y., Su, D. S., Centi, G. & Perathoner, S. Catalysis by hybrid sp(2)/sp(3) nanodiamonds and their role in the design of advanced nanocarbon materials. Chem. Soc. Rev. 47, 8438–8473 (2018).

Wang, L. L. et al. Cooperative sites in fully exposed Pd clusters for low-temperature direct dehydrogenation reaction. ACS Catal. 11, 11469–11477 (2021).

Zhang, J. Y. et al. Tin-assisted fully exposed Platinum clusters stabilized on defect-rich graphene for dehydrogenation reaction. ACS Catal. 9, 5998–6005 (2019).

Ro, I. et al. The role of Pt-FexOy interfacial sites for CO oxidation. J. Catal. 358, 19–26 (2018).

Yoshida, H. et al. XANES study of the support effect on the state of platinum catalysts. J. Synchrotron Radiat. 6, 471–473 (1999).

Lou, Y., Wu, H. L. & Liu, J. Y. Nanocarbon-edge-anchored high-density Pt atoms for 3-nitrostyrene hydrogenation: Strong metal-carbon interaction. Iscience 13, 190–198 (2019).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Munoz, M., Argoul, P. & Farges, F. Continuous cauchy wavelet transform analyses of EXAFS spectra: a qualitative approach. Am. Mineral. 88, 694–700 (2003).

Yang, Y. et al. O-coordinated W-Mo dual-atom catalyst for pH-universal electrocatalytic hydrogen evolution. Sci. Adv. 6, eaba6586 (2020).

Zhang, X. et al. Platinum-copper single atom alloy catalysts with high performance towards glycerol hydrogenolysis. Nat. Commun. 10, 5812 (2019).

Hadjiivanov, K. I. & Vayssilov, G. N. Characterization of oxide surfaces and zeolites by carbon monoxide as an Ir probe molecule. Adv. Catal. 47, 307–511 (2002).

Tan, P. L. Active phase, catalytic activity, and induction period of Fe/zeolite material in nonoxidative aromatization of methane. J. Catal. 338, 21–29 (2016).

Wang, L. C. et al. Non-oxidative dehydrogenation of ethane to ethylene over ZSM-5 zeolite supported iron catalysts. Appl. Catal. B 256, 117816 (2019).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mat. Sci. 6, 15–50 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Perdew, J. P. & Wang, Y. Accurate and simple analytic representation of the electron-gas correlation energy. Phys. Rev. B 45, 13244–13249 (1992).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188–5192 (1999).

Plessow, P. N. Efficient transition state optimization of periodic structures through automated relaxed potential energy surface scans. J. Chem. Theory Comput. 14, 981–990 (2018).

Acknowledgements

This work was supported by the National Key R&D Program of China (2021YFA1502802, 2021YFA1501100), the National Natural Science Foundation of China (21961160722, 92145301, U21B2092, 91845201, 22072162, 21725301 and 21932002), the Liaoning Revitalization Talents Program XLYC1907055, the Dalian National Lab for Clean Energy (DNL Cooperation Fund 202001) and China Petroleum & Chemical Corporation (No. 420043-2). F. H. acknowledges the support from China Postdoctoral Science Foundation (2021M703279) and the Innovation Foundation from Institute of Metal Research (E255L902A1). N. W. hereby acknowledges the funding support from the Research Grants Council of Hong Kong (Project Nos. C6021-14E, N_HKUST624/19 and 16306818). D.M. acknowledges support from the Tencent Foundation through the XPLORER PRIZE. The XAS experiments were conducted in Shanghai Synchrotron Radiation Facility (SSRF) and Beijing Synchrotron Radiation Facility (BSRF).

Author information

Authors and Affiliations

Contributions

H.L. and D.M. conceived the project. Zhi.J. conducted material synthesis and performed the reaction tests. Y.C. and X.W. did the DFT calculations. X.C. and N.W. contributed to the electron microscopy (HAADF-STEM) study. Z.G. and W.Z. carried out the electron energy loss spectroscopy analysis. M.P. and J.X. conducted the X-ray photoelectron spectroscopy. X.Q. and Zhe.J. conducted the X-ray absorption fine structure spectroscopic measurements and analyzed the data. The manuscript was primarily written by Zhi.J., Y.C., D.X., H.L. and D.M. All authors contributed to discussions and manuscript review.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Rajaram Bal and the other, anonymous, reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jia, Z., Qin, X., Chen, Y. et al. Fully-exposed Pt-Fe cluster for efficient preferential oxidation of CO towards hydrogen purification. Nat Commun 13, 6798 (2022). https://doi.org/10.1038/s41467-022-34674-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-34674-y

This article is cited by

-

Tripodal Pd metallenes mediated by Nb2C MXenes for boosting alkynes semihydrogenation

Nature Communications (2023)

-

A sodium-ion-conducted asymmetric electrolyzer to lower the operation voltage for direct seawater electrolysis

Nature Communications (2023)

-

Selective and stable Au-Cu bimetallic catalyst for CO-PROX

Nano Research (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.